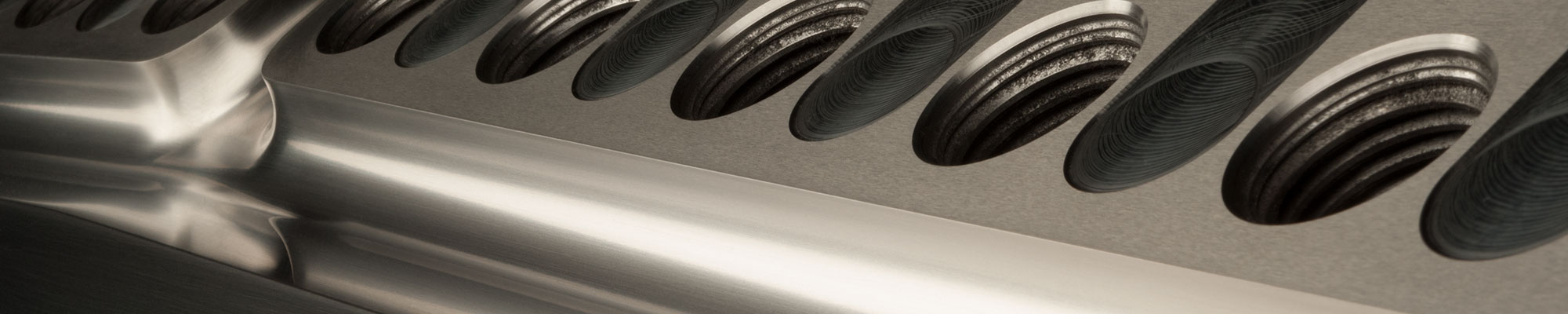

Arc spraying is a low-cost coating process (in view of the high application rates). An arc is ignited between the wire-shaped spray material, which leads to melting of the spray material. Subsequently, the molten spray particles are atomized by a gas, accelerated and applied to the surface of the component.

The workpiece surface is not melted and is only slightly thermally loaded.

In addition to the surface application for coating the workpiece, this method is also used for partial repair of damage and wear points on components such as cylinders, etc.