Other dimensions and weights on request.

Workpieces

Ø 50-600 mm up to 3,000 mm length

Ø 50-500 mm up to 4,000 mm length

Other dimensions and weights on request.

Workpieces up to Ø 500 mm, up to 4,000 mm length

max. layer thickness: 20 mm

Other dimensions and weights on request.

We are certified according to DIN EN ISO 9001:2015. Regular audits ensure that we deliver the highest possible quality. The constantly increasing quality requirements of our customers call upon us to continuously optimize our processes.

Environmental and nature conservation is close to our hearts and is pursued vigorously. This is why we deal openly with the issue related to the handling of hazardous substances and are subject to constant monitoring by public authorities. This means our devices for the protection of air, soil and water are regularly checked.

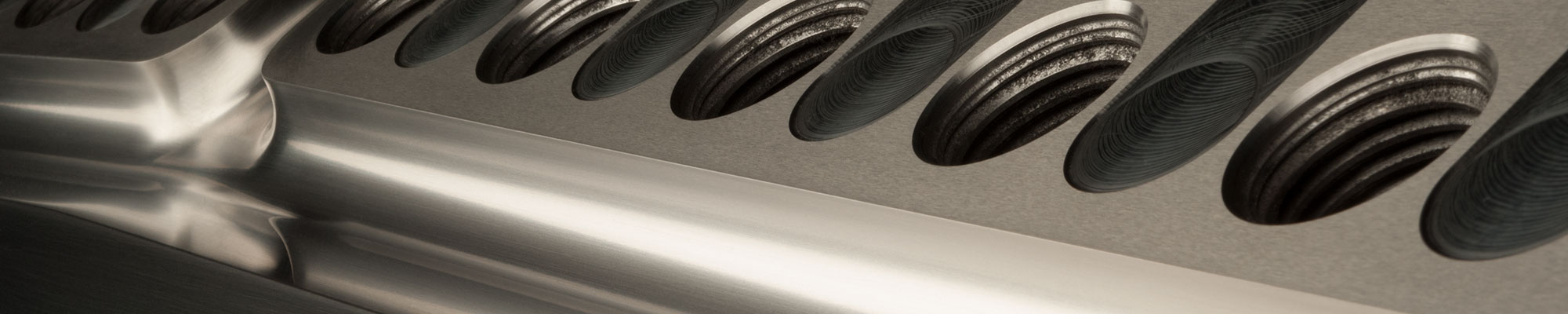

Since 1963 we have been manufacturing high-quality, technical hard chrome plating for a wide variety of applications.

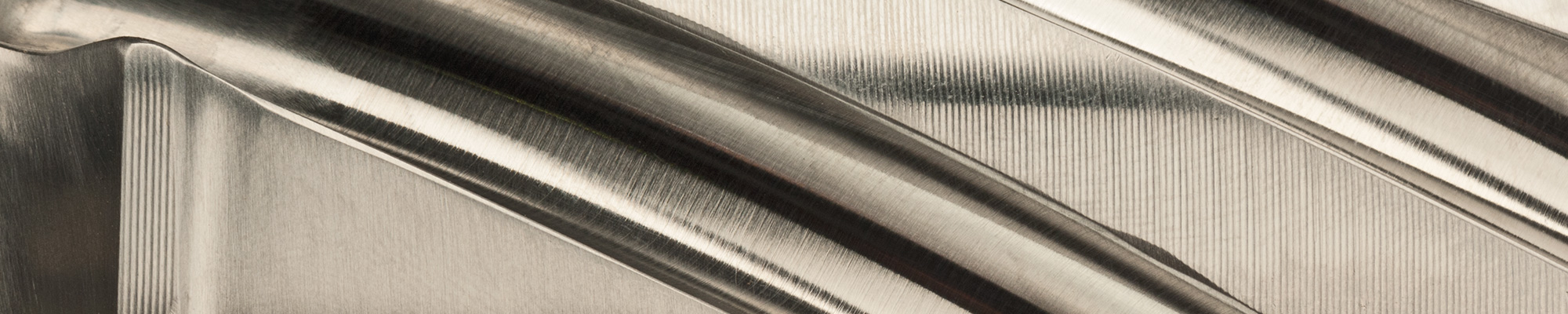

We offer cylindrical grinding, belt grinding, polishing, sandblasting and demagnetising for all surface treatment with hard chrome.

Optimized processes ensure compliance with delivery deadlines and maximum flexibility. Today, customer satisfaction, social commitment and environmental awareness are the cornerstones that define Kreft & Röhrig.